Industrial company increases production efficiency with Checkmk

Who is Polyplast?

Polyplast Müller (PPM) is one of the leading companies in the field of plastics finishing. The family-owned company based in Straelen, Germany produces high-quality granulates by incorporating additives, fillers and color pigments. An important foundation of the company’s success is, among other things, its state-of-the-art technology park. As part of the continuous optimization of its production processes, PPM expanded its IT monitoring with Checkmk so that Polyplast’s IT experts can monitor control systems in addition to the classic IT infrastructure.

The overall support by Checkmk is great. Our wishes are implemented quickly and competently. We are happy with Checkmk.

IT team improves work process efficiency

Before Polyplast Müller (PPM) implemented Checkmk in 2015, the monitoring of servers and network devices required a lot of effort. The IT team checked servers by manually logging in to each system individually or as a response to calls from employees who complained about IT problems. To improve efficiency, PPM wanted to gain more accurate information about the health of the IT infrastructure by using monitoring software. Initially, the plan was to monitor only around 80 diverse server platforms and a few network devices.

Since at that time PPM had no experience with monitoring tools, the IT team was looking for a solution that did not require much prior knowledge. Following a presentation of Checkmk by an employee of a regional system integrator at the end of 2015, PPM had been convinced that Checkmk meets these requirements and decided to implement the Checkmk Enterprise Edition.

PPM additionally booked a support package for the implementation and maintenance of the monitoring by Checkmk. Thanks to the professional support, the implementation of Checkmk went smoothly. Since Polyplast employees received Checkmk training in parallel, they were able to operate the monitoring themselves right from the start.

Since the collaboration was working well, PPM decided in 2017 to include parts of their production environment into the monitoring, too. The company also extended the monitoring of its IT environment by setting up a second Checkmk instance as a remote site for a distributed monitoring in their factory in Bingen in 2019.

The challenge

The IT team was looking for a way to better monitor IT and production assets, and to be able to identify potential limitations at an early stage. They also wanted users without extensive monitoring experience to be able to use the application. Professional support with a personal contact who understands the challenges of production environments was also an important aspect for the IT team in the selection process.

Monitoring for highly secure environments

Today, the monitoring covers over 300 hosts and 12,500 services. PPM monitors the majority of these with its central instance, which runs on a physical Linux server at the company’s headquarters. The monitoring includes about 100 servers, 50 programmable logic controllers (PLCs) in the production area, and several devices from the Internet of Things (IoT). The remaining hosts are network devices such as switches and other IT assets. The remote site at the Bingen plant runs on a virtual Linux server and monitors the IT environment there, but expansion to include production equipment is planned

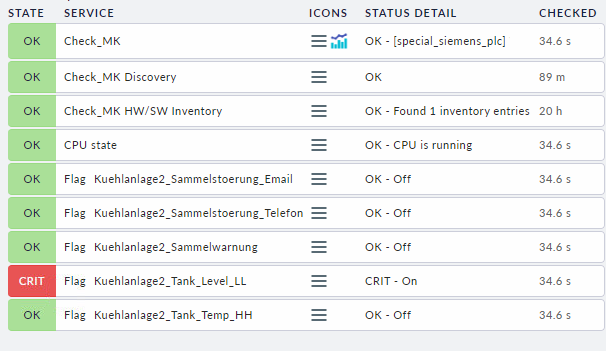

Among other things, PPM monitors PLC systems and uses, for example, the Checkmk special agent for PLCs from Siemens. This is one of the more than 1,900 official Checkmk plug-ins and it enables efficient monitoring of PLCs as well as any connected subsystems.

In addition, IoT devices are also included in the monitoring. In the case of PPM, this involves pressure sensors, temperature sensors or extruders, for example. Depending on the manufacturer, the devices support monitoring via SNMP or Checkmk can access the APIs provided.

The IT team at PPM has made Checkmk a central element of its incident management. By fine-tuning thresholds and alarms, the monitoring reports any problem to various user groups depending on the device type and criticality. It additionally provides a variety of dashboards and permissions for business departments. In this way, mitigation can start as soon as the problem has been detected.

The solution

Polyplast Müller has been using the Checkmk Enterprise Edition since 2015. Thanks to support from Checkmk, the IT team is able to monitor not only the IT infrastructure, but also the production facilities. Checkmk has additionally been customized so that it is suitable for monitoring service providers and VPN accesses.

Notifications tailored to the industry

In production, notifications sent by email are often insufficient or too slow. Accordingly, PPM uses their telephone system to inform the responsible employees by linking it to the monitoring. When Checkmk reports an alert, it sends a message to the telephone system, triggering a script. Then, the telephone software uses IP telephony to call the phone numbers stored for the specific alarm. When a contact answers the call, the phone system converts part of the Checkmk alert into a voice message and reads it to the contact.

PPM’s IT experts have built different procedures depending on the system being monitored, so that the telephone system can inform several contacts at once in the event of an alarm or archive the voice message after a successful transmission.

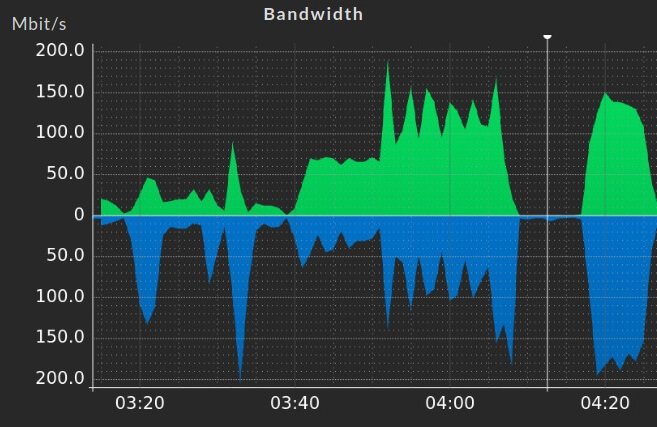

PPM additionally monitors access by service providers to its facilities with Checkmk. The monitoring solution detects when a VPN port is used. Using scripts for the company firewall, PPM logs remote access and can track whether service providers have made any changes to their systems.

PPM has used Checkmk to improve the efficiency of its IT department as well as its control technology. The company can ensure that all assets are working optimally in all areas. Through end-to-end monitoring, various departments can accurately plan and coordinate maintenance work. This results in greater precision and less unplanned work for the IT and control engineering team.

At present PPM is working on the expansion of its monitoring in the factory in Bingen in order to monitor the production facilities there as well. In addition, the machinery is constantly changing as the company modernizes equipment or replaces it with new models. Checkmk is highly customizable and gives Polyplast all of the freedom it needs to securely monitor new systems as well.

The advantages

Thanks to Checkmk, Polyplast Müller is able to ensure optimal operating conditions at all times. Previously, the company could only identify problems after an employee had reported them or as part of a manual check. Some bottlenecks also remained undetected. Now Checkmk alerts the appropriate department and Polyplast can follow up on any anomaly efficiently and directly.

Those responsible for the maintenance, PLC and other teams are provided with all relevant information immediately and tailored to their needs.